WHTB : A LEADING GLASS MANUFACTURING COMPANY

Beijing Wuhua Tianbao Glass Co., Ltd (WHTB Glass) was founded in early 2002 with a total investment of USD 46 million, is a leading provider of processed glass products. It covers an area of 80,000 m² with 110,000 m² floor space of building and have an annual processing capacity of 1,500,000 m².

The main products includes solar reflective glass, Post – temperable Low-E, insulated glass units, laminated glass, tempered glass& heat-strengthened glass, curved tempered glass, fire-resistant glass, digital printer ceramic frit glass, silk-screen glass, as well as composite glass products. The quality of our products are strictly in accordance with the standard of BS/EN, AS/NZS, ASTM, ANSI standards etc.

With the largest production facility in China, specialized CNC machinery and oversized glass manufacturing capabilities, WHTB Glass Group is ideally set up to produce both high-volume and one-off specialty glass products cost effectively and quickly. Whatever your project demands — from exterior high-rise windows to large-capacity glass for storefronts or showrooms — WHTB Industries can manufacture and fabricate the glass products you need to your exacting design and technical specifications.

With our large-capacity glass manufacturing capabilities, WHTB can accommodate short lead times, offer oversized capabilities and large quantity glass units that exceed current building codes and provide decades of performance.

GLASS PRODUCTS :

1.LOW E COATING GLASS

2.SOLAR REFLECTIVE GLASS

3.INSULATED GLASS

4.HEAT TREATED GLASS

5.CURVED TEMPERED GLASS

6.HEAT SOAKED GLASS

7.LAMINATED GLASS

8.SENTRY GLASS PLUS

9.SOUND CONTROL GLASS

10.SILK SCREEN GLASS

11.DIGITAL PRINTED GLASS

12.PRICISION DRILLING AND MILLING

13.POINT SUPPORTED GLASS SYSTEM

14.INTERNAL GLAZING

LOW E GLASS

Glass is one of the most popular and versatile building materials used today, and it provides a dramatic aesthetic. But the beauty of glass is pointless if the people inside the building are uncomfortable or if energy inefficiency makes the building too expensive to operate.

Low-emissivity (low-e) glass coatings were developed to minimize the amount of ultraviolet and infrared light that can pass through glass without compromising the amount of visible light that is transmitted. A microscopically thin transparent coating allows Low-E glass to reflect exterior heat in warm temperatures and hold in heat during cold temperatures, making buildings light, bright and energy-efficient. WHTB offers two types of low-e coated glasses: Single silver Low-E and Double silver Low-E.

SINGLE SILVER LOW E GLASS

Within the coating structure of single silver Low-E glass, there is one silver layer. Single Silver Low-E glass has been widely used in various buildings at different locations worldwide.

Features

- Visible light transmittance— adequate indoor natural daylighting.

- Solar energy transmittance — a wide range of shading coefficient SC available, for different geological locations.

- High far infrared reflectance — low U-value, reduced thermal transfer due to temperature difference.

DOUBLE SILVER LOW E GLASS

Within the coating structure of double silver Low-E glass, there are two silver layers. While maintaining the same visible light transmittance, it has lower shading coefficient, SC, than single silver Low-E glass. In other words, it filters the sunshine as a cool lighting source to a larger extent and provides a solution to energy efficiency in design of high transparency architectures.

Features

- Higher visible light transmittance — ensuring better natural lighting

- Extremely low solar heat transmittance — effectively impeding solar heat radiation.

TRIPLE SILVER LOW E GLASS

Triple Silver Low E Glass is the most complicated and advanced series of Low-E glass in the world which can be produced by few companies. It is because the radiation transmittance reaches to only 0.01% which is perfect technology data, it has the wide applications in many fields.

- High level of visible light transmission: provide a natural lighting, with a neutral exterior appearance.

- Very low shading coefficient: effective in reducing solar heat radiation from reaching the building interior, especially for infrared heat radiation.

- Very low heat gain or heat loss value (U Value): good heat Insulated, effectively reduce heat gain in summer and heat loss in winter.

SOLAR REFLECTIVE GLASS

WHTB solar reflective glass range is an offline coated glass manufactured by magnetron sputtering deposition under vacuum conditions onto float glass. The manufacturing process and type of materials with which the glass is coated ensure that this coating offers excellent resistance and stability over time.

These qualities enable this coated glass to be processed (e.g. tempered, laminated, bent, enamelled etc.), while still retaining its aesthetic and technical benefits.

INSULATED GLASS

By combining Low-E coatings, standard and high performance tinted glass, reflective coatings, silkscreened patterns, laminated glass products and more, a wide variety of insulating Glass compositions are available to satisfy a wide range of performance and aesthetic requirements. IG units can be fabricated to meet state energy and safety codes, sound control and seismic requirements, impact, bullet, hurricane and blast resistance requirements. IG units can be designed to reduce heat loss and solar heat gain entering the building, with a minimal reduction of visible light transmittance. Insulating glass units are fabricated according to project specifications.

IG units can be constructed using a large variety of glass products to achieve desired aesthetics, meet design criteria, safety codes and/or to improve solar control and thermal performance. Glass options include clear, low iron, Low-E’s, standard or high performance (spectrally selective) tints, reflective, silk-screened, spandrel, laminated, decorative and wired glass. The glass lite of an IG unit can be annealed, heat-strengthened, tempered or laminated.

HEAT TREATED GLASS

Heat-treated glass is a general term used in the glass fabrication industry to describe glass that has been processed through a tempering oven to change its strength and breakage characteristics (i.e., the size and/or shape of the glass pieces after breakage). There are two distinct heat-treated products, heat-strengthened glass and fully tempered glass, as defined in ASTM C1048 Standard Specification for Heat-treated Flat Glass–Kind HS, Kind FT Coated and Uncoated Glass. Compared to annealed glass (non-heat-treated glass), both have increased strength to resist higher levels of impact, mechanical load and thermal stress. Heat-strengthening adds strength to the glass while limiting the change in its breakage characteristics. Tempered glass is stronger than heat-strengthened glass and significantly reduces the broken piece size to meet the safety glazing standards.

CURVED TEMPERED GLASS

Curved tempered glass or curved heat-strengthened glass, is achieved by heating glass to softening temperature and then bending by weight or external force, followed by fast cooling with air blowing. WHTB adopts advanced synchronized roller way formation technology, being able to produce various curved tempered glass products, such as round-shaped, J-shaped etc., with high formation precision and quality. If required by application, curved insulating glass, curved laminated glass, or curved tempered laminated coated insulating glass by use of bendable coated glass, can also be manufactured.

HEAT SOAKED GLASS

Reduce the possibility of spontaneous tempered glass on site breakage by specifying Heat Soaked Glass from WHTB. This exclusive process provides an increased level of security by reducing site breakage of tempered glass.

Utilizing the latest in digital recording equipment, WHTB is able to automatically record the batch data of the heat soaked glass, guaranteeing customers that the stringent EN 14179 Standard.

LAMINATED GLASS

Add unsurpassed safety, security and performance to your glazing applications with WHTB’s line of Laminated Glass products. Choosing the safety, security and serenity of laminated glass no longer means limiting yourself in regards to glass type, colour or size. WHTB Laminated Glass is available in all glass types, including, clear, tinted, reflective, Low-E, spandrel, ceramic frit and silk-screened. All the while offering unmatched quality, advanced features and oversized capabilities to match WHTB’s heat treated, heat soaked and insulated glass offerings.

A wide variety of interlayer thickness, opacities and colours are available in:

- PVB Laminated Glass

- Polycarbonate Laminated Glass

- SentryGlas® Plus Laminated Glass

The most common laminated glass units are constructed with two plies of glass permanently bonded together with one or more interlayers. The most important characteristics of laminated glass are fall-out protection due to the ability of the interlayer to support and hold the glass when broken as well as the reduced ability to penetration the opening. The ability to resist various kinds of penetration is dependent upon a number of factors including thickness of the glass and the type of interlayer selected. Laminated glass also offers a greater availability of coatings than monolithic glass. Low-E coatings which cannot be exposed, and therefore cannot be used with monolithic glass, can be used inside a laminated unit where they are

protected. Laminated glass units also have more aesthetic possibilities than monolithic glass. The interlayers used in laminated glass are available in a variety of colours and opacities. In addition, the Low-E coating and silk-screen pattern, if desired, are Laminated Glass applied to the exterior ply of glass leaving the interior ply available for additional treatment. For a spandrel location, a full coverage opaque ceramic frit can be applied to the inner face (surface #4). For vision areas where daylight is desired but view through needs to be minimized, a translucent ceramic frit can be applied to surface #3.

SENTRYGLAS PLUS

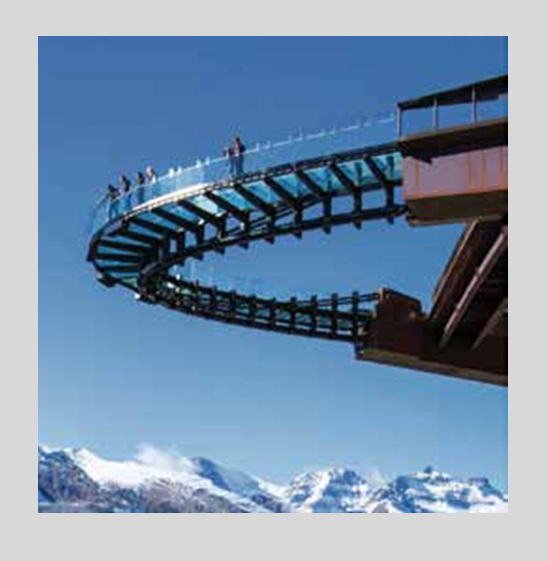

For glass that’s more than glass DuPont™ SentryGlas® Plus creates new glazing opportunities by changing the way glass performs and providing new design options for architects and building designers. Tests have proven that SentryGlas®

Plus has excepti onal residual strength, even when both lite of glass are broken (sky walk photo). This brings greater peace of mind to building owners and occupants in locations that experience typhoons or hurricanes and makes it possible to specify safer laminated glass for point-supported glazing systems, canopies, skylights and railings. SentryGlas® Plus is an ideal product for complex glazing projects that

require increased strength and enhanced appearance. The benefits of SentryGlas® Plus are not only confined to complex projects. Glazing systems that utilize SGP are typically lighter than their PVB counterparts. This can result in larger panels, reduced number of support fittings and a lighter weight support structure that enhance the visual impact. There are significant performance benefits that can be achieved when specifying SentryGlas® Plus laminated products from WHTB.

SOUND CONTROL GLASS

Shielding a building’s environment from increasing noise levels, especially near airports and busy highways, is a critical factor in the specification of glazing materials for both new and renovated structures. Laminated glass is a proven, effective solution for acoustical protection. Sound Control Glass is a perfect solution for insuring exceptional levels of sound insulation. It not only provides insulation for impact and airborne noise but also maintains the safety and

security properties of laminated glass. WHTB Sound Control Glass is the ultimate solution, it is an excellent combination of Safety and Acoustic performance with all of the benefit of laminated glass, and can be combined with solar absorbing laminated glass and any of our tinted interlayers for added desirable effects.

Sound is a wave phenomenon characterized in frequencies (Hz), speed (approximately 340 m/sec through air) and amplitude (amount of energy in the sound wave). WHTB Sound Control Glass is designed to decouple and disseminate sounds waves for superior sound damping performance. This system targets sounds in the 1000 – 3000 Hz range which is the “noise transparency” range that allows the most irritating of sounds to penetrate windows.

Monolithic glass is a relatively light substance and is also hard, therefore allows sound to pass For installation in Building Areas: quite easily, whereas the Sound Control interlayer is a soft and flexible substance that is not inclined to allow sound to pass through it eliminating noise by approximately 50%.

SILK-SCREENED GLASS

WHTB silk-screened ceramic enamel frit products offer building designers exciting and different ways to customize exterior and interior glass, by using standard and custom screened patterns in a variety of colours. Silk-Screened glass is offered monolithically, in insulating glass units, or as laminated glass, providing beauty, safety and functionality. Available in one-piece orders or high-volume runs, silk screened decorative glass is custom made by transferring a silk-screen image to the glass and then processing it through a horizontal tempering furnace. Each individual lite is screen-printed with the desired pattern and ceramic enamel frit colour. The ceramic frit can be silk-screened onto the glass substrate in one of three standard patterns, dots, lines, holes, or in a full-coverage application. In addition, custom patterns can be easily duplicated on the glass. Depending on the pattern and the colour, the glass lite can be made transparent, translucent or opaque. WHTB offers a variety of silk-screened decorative glass products to satisfy a wide range of applications. Light frit colours and certain pattern designs can cause enhanced brightness when viewed from indoors under certain daylight and background sky conditions, while dark frit colours will tend to reduce glare. Applications include transparent and translucent silk-screened glass for interior applications, including glass doors, partitions, handrails, glass ceilings, floors, bathrooms, elevator walls, shower enclosures, court walls for racket sports and sneeze guards for food service.

DIGITAL PRINTED GLASS

From the initial design stage, through the value engineering process, we can assist architects designers and engineers with calculating the long-term savings enabled by digital ceramic printed glass. Digital ceramic in-glass printing meets complex functional performance requirements. It enables control of all special elements of architectural and designed glass

- TRANSLUCENCY/OPACITY

- LIGHT DIFFUSION AND TRANSMISSION

- SOLAR HEAT GAIN COEFFICIENCY

- ENERGY EFFICIENCY

- PRIVACY LEVELS

- ELECTRICAL CONDUCTIVITY

- SLIP RESISTANCE

- ANTI-BIRD COLLISION

ANYWHERE– Exterior and interior durability. Ceramic ink resistance after tempering is equal to glass resistance.

ANYDESIGN– Personalized, opaque, transparent and textured-look effects. Micro-drop precision enables highly detailed, accurate photorealistic and graphic designs and gradients.

ANYNEED– Any aesthetic requirements and a wide range of functional applications. Micro-drop precision supports light diffusion, light transmission, energy efficiency, sun control, temperature control, privacy levels and other functional requirement.

ANYCOLOR– Multi-colour printing in a single glass. Digital in-glass printing technology enables truly limitless multi-colour designs with ceramic ink durability.

ANYSIZE– From small panes to building facades, with perfect-registration multi-pane printing. Modular printer hardware and advanced printing software enable simple and flexible printing on glass panes.

ANYCONDITIONS– Full resistance to weather and chemicals. Ceramic inks fused into the glass stand up to harsh weather conditions and are scratch and acid-resistant, ideal for exposed, high-traffic and graffiti-prone installations.

PRECISION DRILLING & MILLING

Glass entrances, shower doors, railing and furniture glass need a special degree of attention. WHTB uses a precision Computerized Numeric Control (CNC) fabrication machine to drill, mill, polish and cut holes and notches with the exact precision and quality required for these jobs. Polishing and Edgework WHTB has the edge when it comes to polished edges, offering four standard edge types: flat polish, flat grind, mitered polish and mitered grind. Flat and mitered edges are available on all glass thicknesses, with mitres ranging from 0 to 45 degrees.

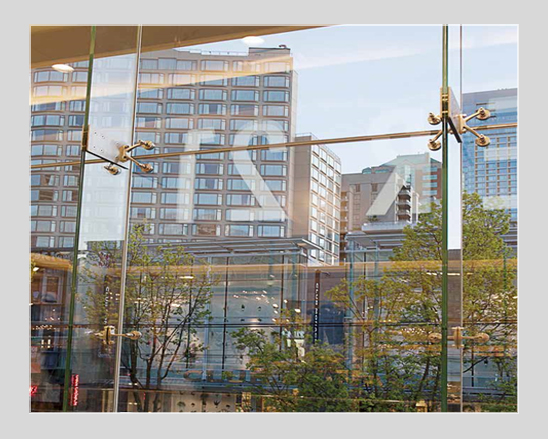

POINT SUPPORTED GLASS SYSTEM

Create a statement on your next glazing project with Point-Supported System. This striking all-glass glazing option is ideally suited for vertical walls, entrances and canopies, providing architects the greatest level of transparency in today’s facades and eliminating the need for metal mullions. Point supported systems can incorporate insulating glass with or without Low-E, laminated glass or monolithic tempered glass.